The Overlooked Role of Renewable Naphtha in Decentralized Bio-Based Polymer Production

Renewable naphtha is driving decentralized bio-polymer production, enabling circular economies and lowering emissions in the global petrochemical industry.

NEWARK, DE, UNITED STATES, June 9, 2025 /EINPresswire.com/ -- 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧: 𝐀 𝐒𝐡𝐢𝐟𝐭 𝐢𝐧 𝐏𝐞𝐫𝐬𝐩𝐞𝐜𝐭𝐢𝐯𝐞

Renewable naphtha has gained steady attention as a sustainable alternative to fossil-based naphtha in the petrochemical industry. Often highlighted for its applications in steam cracking to produce ethylene and propylene, renewable naphtha is largely viewed through the lens of decarbonizing conventional plastic production. However, a deeper look reveals a lesser-known but increasingly significant role: its use in decentralized, region-specific bio-based polymer production. As global supply chains are restructured around circular and localized models, renewable naphtha emerges not just as a green feedstock but as a key enabler of next-generation, modular manufacturing systems that bypass the limitations of centralized infrastructure.

𝐋𝐞𝐚𝐫𝐧 𝐚𝐛𝐨𝐮𝐭 𝐭𝐡𝐞 𝐜𝐨𝐧𝐭𝐫𝐢𝐛𝐮𝐭𝐢𝐨𝐧 𝐨𝐟 𝐞𝐚𝐜𝐡 𝐬𝐞𝐠𝐦𝐞𝐧𝐭 𝐨𝐟 𝐭𝐡𝐞. 𝐑𝐞𝐚𝐝 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.futuremarketinsights.com/reports/sample/rep-gb-7740

𝐅𝐫𝐨𝐦 𝐂𝐞𝐧𝐭𝐫𝐚𝐥𝐢𝐳𝐞𝐝 𝐏𝐞𝐭𝐫𝐨𝐜𝐡𝐞𝐦𝐢𝐜𝐚𝐥𝐬 𝐭𝐨 𝐃𝐞𝐜𝐞𝐧𝐭𝐫𝐚𝐥𝐢𝐳𝐞𝐝 𝐁𝐢𝐨-𝐏𝐨𝐥𝐲𝐦𝐞𝐫𝐬

Historically, petrochemical production has thrived on centralized, large-scale facilities often located near oil refineries or major ports. These hubs rely on fossil naphtha as a feedstock, transported over long distances to produce intermediates like ethylene and propylene, which are then polymerized into widely used plastics such as polyethylene (PE) and polypropylene (PP). While this model has driven economies of scale, it also locks industries into carbon-intensive logistics and inflexible production routes.

The emergence of renewable naphtha, derived from sustainable feedstocks like used cooking oil, tall oil, and bio-waste, allows for an entirely different production paradigm. Modular biorefineries capable of producing bio-naphtha are now being developed in regions with abundant biomass but limited fossil infrastructure. For example, Neste in Finland and UPM Biofuels have pioneered small-scale production plants that integrate with local biomass supply chains. These facilities feed directly into localized polymer manufacturing, enabling rural or industrial regions to produce high-demand bio-polymers without relying on international fossil supply routes. In this context, renewable naphtha acts as a catalyst for decentralizing chemical production and promoting regional economic resilience.

𝐑𝐞𝐧𝐞𝐰𝐚𝐛𝐥𝐞 𝐍𝐚𝐩𝐡𝐭𝐡𝐚 𝐚𝐬 𝐚 𝐂𝐢𝐫𝐜𝐮𝐥𝐚𝐫 𝐄𝐜𝐨𝐧𝐨𝐦𝐲 𝐄𝐧𝐚𝐛𝐥𝐞𝐫

The use of renewable naphtha aligns with the broader circular economy goals of reducing waste, lowering greenhouse gas emissions, and improving resource efficiency. Unlike traditional fossil naphtha, renewable variants are increasingly sourced from waste fats and oils, making them attractive not only for their carbon profile but also for their compatibility with circular feedstock strategies.

Lifecycle assessments (LCAs) conducted by industry leaders such as Borealis and TotalEnergies have demonstrated that bio-naphtha can reduce carbon emissions by up to 80% compared to fossil alternatives when derived from waste-based sources. In applications like the production of bio-based polyethylene (bio-PE), renewable naphtha offers full compatibility with existing steam crackers and polymerization units, eliminating the need for expensive retooling. This drop-in compatibility, combined with its sustainable origin, positions renewable naphtha as a dual lever for carbon reduction and economic feasibility in the transition to circular materials.

𝐁𝐫𝐨𝐰𝐬𝐞 𝐭𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐑𝐞𝐩𝐨𝐫𝐭! https://www.futuremarketinsights.com/reports/renewable-naphtha-market

𝐅𝐞𝐞𝐝𝐬𝐭𝐨𝐜𝐤 𝐃𝐲𝐧𝐚𝐦𝐢𝐜𝐬 𝐚𝐧𝐝 𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐃𝐞𝐩𝐞𝐧𝐝𝐞𝐧𝐜𝐢𝐞𝐬

The production of renewable naphtha is closely tied to the availability of specific bio-based feedstocks. Used cooking oil and animal fats are prevalent in Europe and parts of North America, while tall oil, a byproduct of the paper and pulp industry, is widely used in Nordic countries. In contrast, countries like Brazil and India are experimenting with sugarcane-derived ethanol and municipal solid waste (MSW) to generate renewable hydrocarbons, including naphtha.

These regional variations have a direct impact on the scalability and cost of renewable naphtha production. For instance, Finland benefits from a mature tall oil supply chain that supports Neste’s bio-refining operations, whereas emerging economies may require infrastructure upgrades or policy incentives to process urban waste into viable feedstocks. As a result, the global renewable naphtha market exhibits significant diversity, with localized production strategies often driven by feedstock proximity and governmental support.

𝐔𝐧𝐯𝐞𝐢𝐥𝐢𝐧𝐠 𝐃𝐞𝐦𝐚𝐧𝐝 𝐃𝐫𝐢𝐯𝐞𝐫𝐬 𝐢𝐧 𝐁𝐢𝐨-𝐁𝐚𝐬𝐞𝐝 𝐎𝐥𝐞𝐟𝐢𝐧𝐬 𝐚𝐧𝐝 𝐏𝐥𝐚𝐬𝐭𝐢𝐜𝐬

The demand for renewable naphtha is inextricably linked to the rising appetite for bio-based olefins and polymers. Major chemical companies such as Braskem, SABIC, and Dow are increasingly committing to bio-based product portfolios, propelled by both consumer pressure and corporate sustainability targets. Bio-polyethylene and bio-polypropylene are two materials that can be derived directly from ethylene and propylene cracked from renewable naphtha.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: 𝐁𝐞𝐭𝐰𝐞𝐞𝐧 𝐏𝐨𝐥𝐢𝐜𝐲 𝐚𝐧𝐝 𝐏𝐫𝐨𝐟𝐢𝐭𝐚𝐛𝐢𝐥𝐢𝐭𝐲

While technological readiness and market interest in renewable naphtha are evident, its future hinges on both supportive policy frameworks and economic viability. The European Union’s Fit for 55 package and the United States’ Inflation Reduction Act have begun to tilt the scales in favor of green feedstocks through tax credits and emissions trading mechanisms.

𝐄𝐧𝐞𝐫𝐠𝐲 𝐚𝐧𝐝 𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥 𝐂𝐡𝐞𝐦𝐢𝐜𝐚𝐥𝐬: https://www.futuremarketinsights.com/industry-analysis/energy-and-environmental-chemicals

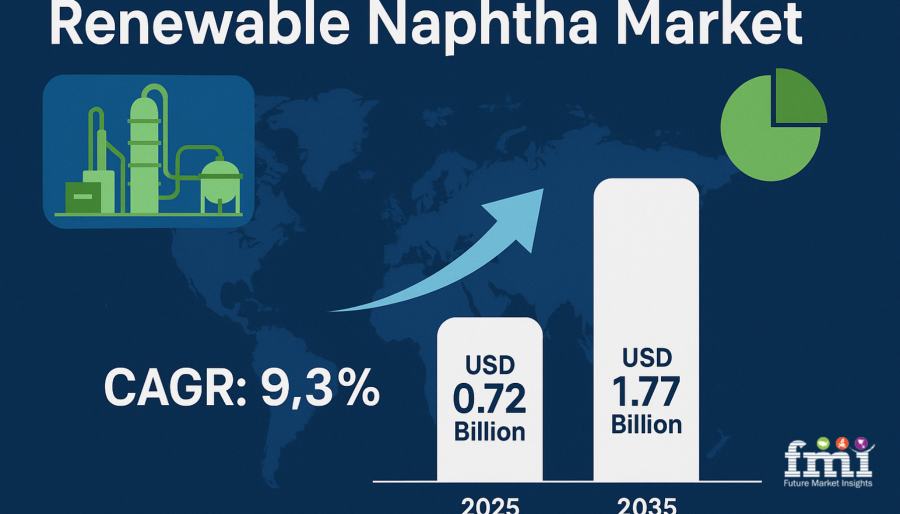

This price sensitivity can challenge smaller producers or developing markets, which may struggle to maintain profitability without subsidies or long-term offtake agreements. Nonetheless, as more brand owners adopt Science-Based Targets and push for Scope 3 emission reductions, the willingness to pay a green premium is expected to rise, indirectly strengthening the demand outlook for renewable naphtha. According to Future Market Insights (FMI), the market size is expected to be USD 729.3 million in 2025, and the industry is expected to expand significantly, reaching USD 1,774.5 million by 2035, at a CAGR of 9.3%.

𝐀 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐄𝐧𝐚𝐛𝐥𝐞𝐫 𝐨𝐟 𝐋𝐨𝐜𝐚𝐥𝐢𝐳𝐞𝐝 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲

Renewable naphtha is often discussed as a decarbonization tool within existing petrochemical infrastructure, but its role in enabling decentralized, modular polymer production is underappreciated. In a world shifting toward circularity, regional resilience, and supply chain localization, renewable naphtha offers more than just an emissions advantage — it offers a pathway to democratizing the production of sustainable materials. As feedstock innovation, policy backing, and corporate ESG agendas align, renewable naphtha may very well become the foundation of a new, decentralized industrial ecosystem.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Product Type:

In terms of Product Type, the industry is divided into Light Naphtha, Heavy Naphtha

By Application:

In terms of Application, the industry is divided into Fuel Blending, Feed for H2 Production, Feed for Plastics Production

By Region:

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East and Africa (MEA).

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Automotive Bioplastic Market: https://www.futuremarketinsights.com/reports/automotive-bioplastic-market

Lithium and Lithium Ion Battery Electrolytes Market: https://www.futuremarketinsights.com/reports/lithium-and-lithium-ion-battery-electrolytes-market

Vulcanization Accelerators Market: https://www.futuremarketinsights.com/reports/vulcanization-accelerators-market

Viscosity Index Improvers Market: https://www.futuremarketinsights.com/reports/viscosity-index-improvers-market

Mass Finishing Consumables Market: https://www.futuremarketinsights.com/reports/mass-finishing-consumables-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Business & Economy

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release